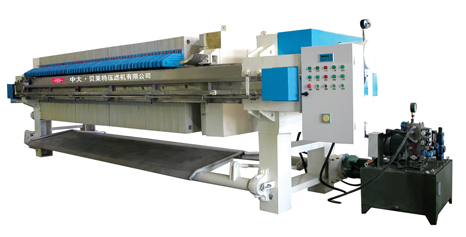

- Filter plates are made of strengthened polypropylene through mold pressing, high in strength, light in weight, corrosion resisted, non-poisonous and odorless;

- Programmed arm tie, electrical system controlled, hydraulic system controlled or computer controlled, completely automatic;

- Hydraulic devices are adopted for pressing and releasing filter plates with maximum pressing pressure of 25 MPa, and automatic pressure maintaining by using electro connecting pressure gauge;

- The maximum filtering pressure is 1.0 MPa to ensure optimum conditions of cake formation and pressure filtration;

- Simple in operation, safe and labor saving, use buttons on the control panel to control continuous actions, and safe in operation with multiple safety devices.

|

- Solid-liquid separation in chemical, metallurgy, pharmaceutical, light industry, coal mining, foodstuff, textile, environmental protection, energy source and other industries.

|